The Ultimate Guide to Short Drama: Captivating Stories in Minutes

Short dramas have revolutionized digital storytelling by delivering powerful narratives in condensed formats. These bite-sized productions combine compelling plots with emotional depth, perfect for today’s fast-paced consumption habits.

Why Short Dramas Are Dominating Digital Platforms

The rise of short-form video platforms has created unprecedented demand for quality short drama content. Unlike traditional formats, these mini-stories achieve maximum impact through:

• Focused storytelling without filler content

• High emotional density in brief runtime

• Mobile-optimized viewing experiences

• Shareability across social media platforms

Creating Compelling Short Dramas

Successful short dramas require meticulous planning despite their brief duration. Key elements include:

Character Development: Establish immediate audience connection through relatable protagonists

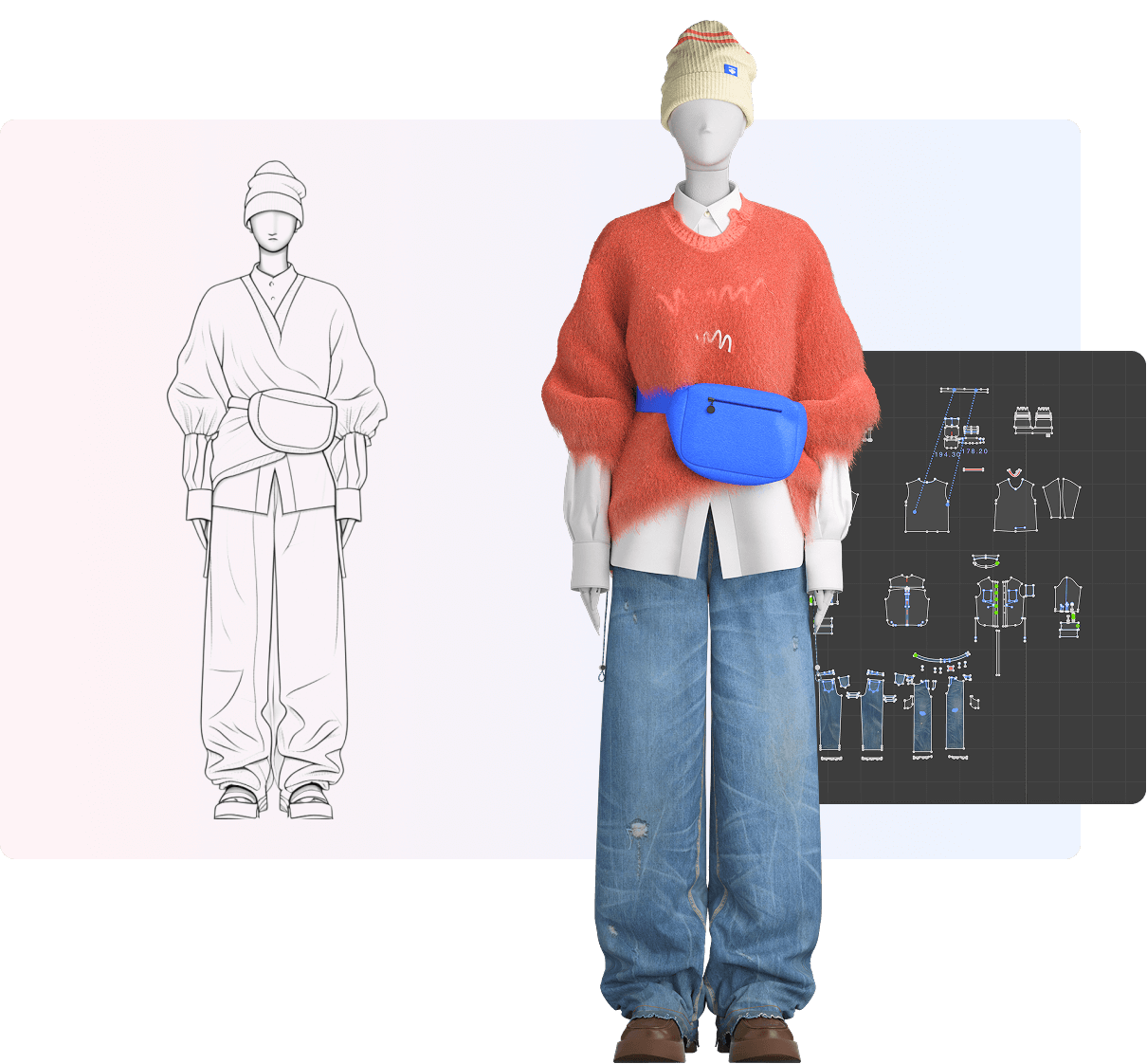

Visual Storytelling: Utilize cinematography to convey meaning without dialogue

Pacing: Maintain narrative momentum through strategic scene transitions

For exemplary execution of these techniques, explore this award-winning Short Drama that masterfully balances emotional depth with concise storytelling.

FAQs About Short Drama Production

What’s the ideal length for short dramas?

Most successful productions range between 3-15 minutes, allowing complete narrative arcs while maintaining viewer engagement.

How do short dramas generate revenue?

Through platform partnerships, brand integrations, and subscription models that reward quality content creation.

Start Your Short Drama Journey Today

The accessibility of production tools and distribution platforms makes this the perfect time to create your first short drama. Begin with simple equipment, focus on authentic storytelling, and gradually develop your unique visual language.

Ready to captivate audiences with your storytelling? Start scripting your first short drama today and join the revolution of meaningful micro-content creation.